-

Français

Français

-

English

English

No products

Prices are tax included

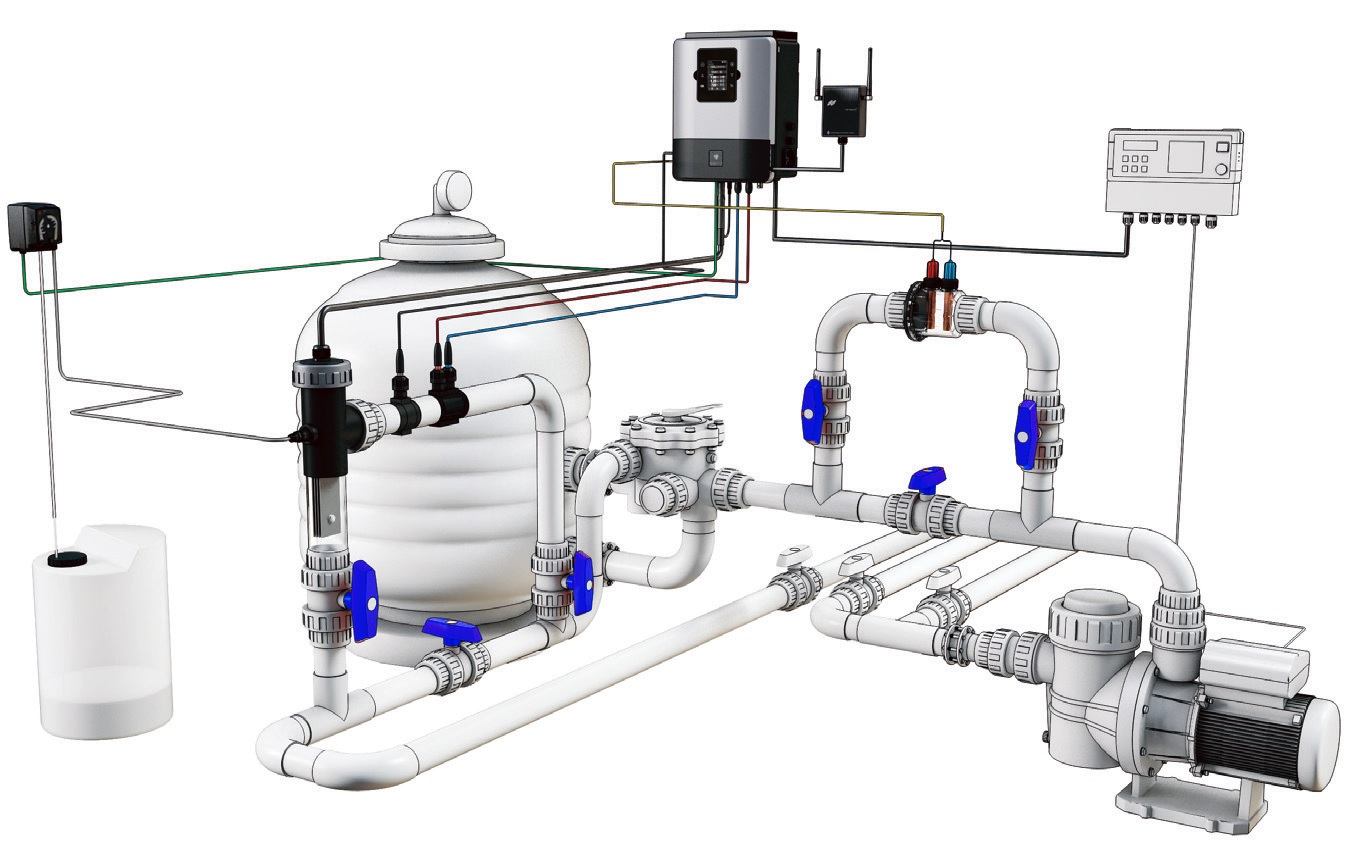

Sugar Valley Aquascenic

Description

Disinfection inexpensive and easy to install in any type of pool.

Works without salt.

Eliminates the use of chlorine and chemicals.

Increases the filtration power.

Flocculant activity, algaecide and bactericide high.

Characteristics

Low salt / electrolysis hydrolysis:

Water is composed of two parts of hydrogen and one part of oxygen (H2O). The word "hydrolysis" means decomposition by reaction with water. The hydrolysis process generates hydrogen and oxygen by means of electricity and water.

When an electric current passes through the water, it breaks the chemical bonds, the negative charges or the oxygen ions migrate to the positive electrode (anode) and the positively charged hydrogen ions are attracted to the negative electrode (cathode) . The following decomposition reaction occurs:

Electric energy + 2H2O -> 2H2 + O2

As a result, this produces an additional negative element because there is more electron (electrical energy) in the combination than protons. There is now only one negatively charged hydroxide, known as the hydroxyl ion (OH-).

Various side reactions occur during hydrolysis which also produce ionic species with oxidizing and disinfecting activity, such as ozone (O3), monoatomic oxygen (O1) and hydrogen peroxide (H2O2).

The circuits of our electronic device transform the current (220 V, 50 Hz) into a direct current low voltage and amperage high. This current is fed by special titanium electrodes that are activated on the surface with noble metals, the electrodes are immersed in water as it flows through a specific device.

The surfaces of these insoluble electrodes generate a combination of the most powerful oxidizing agents available for water disinfection, eliminating the need for chemicals.

If a small amount of salt is incorporated in the treatment (1 - 2 g of salt per liter of water), either to fill a lack of conductivity or to generate a tangible residual level, the system will also generate a level of chlorine residual by low salt electrolysis.

The products are generated, act, decompose and are then regenerated. The residual disinfectant produced by electrolysis does not cause any adverse effect on the eyes, skin or health of the swimmers.

There is no need to worry about salt deficiency in the water, as the system would continue to disinfect in hydrolysis mode. The chlorine generated by the electrolysis process destroys organic matter and pathogens in the water, before finally turning into sodium chloride (common salt)

Copper ionisation (CU) and silver (AG)

The combination of two components with disinfectant activity, copper and silver, greatly increases the efficiency of all our systems. If, in the case of cold water, they are supplemented by the presence of a third compatible agent (chlorine), this activity increases geometrically.

The addition of metal ions as disinfectants in water seems to have been practiced since antiquity. The Phoenicians used to place silver coins in ceramic and copper amphorae to help preserve the water.

In 1971, C.V. James demonstrated that all silver salts are bactericidal and that silver particles dissolved in water at a concentration of 10-5 are toxic to E. coli and Bacillus bacteria types.

The currently available Cu / Ag ionization technology was initially developed by NASA at the beginning of the space program, in search of a safe method of purifying water to take to space.

Several airlines use silver ions to preserve the water they give to passengers during flights.

Silver ions are added to beverages, beers, liqueurs and wines in more than 70 countries.

Oxidation reactions

The reactions producing ions at the anode are:

Cu ++ Cu2 + + 2e-

Ag ++ Ag + + 1e